Ever wondered what makes your food packaging so reliable and secure? The answer might lie in the meticulous work of a hottack tester operator. As part of Vived Management, our dedicated professionals ensure the integrity and efficiency of flexible packaging materials through their expertise in hot tack testing. Let's dive into a day in the life of a J&B hottack tester operator and explore the routine that safeguards the products you use every day.

The Morning Hustle: Setting the Stage for Precision

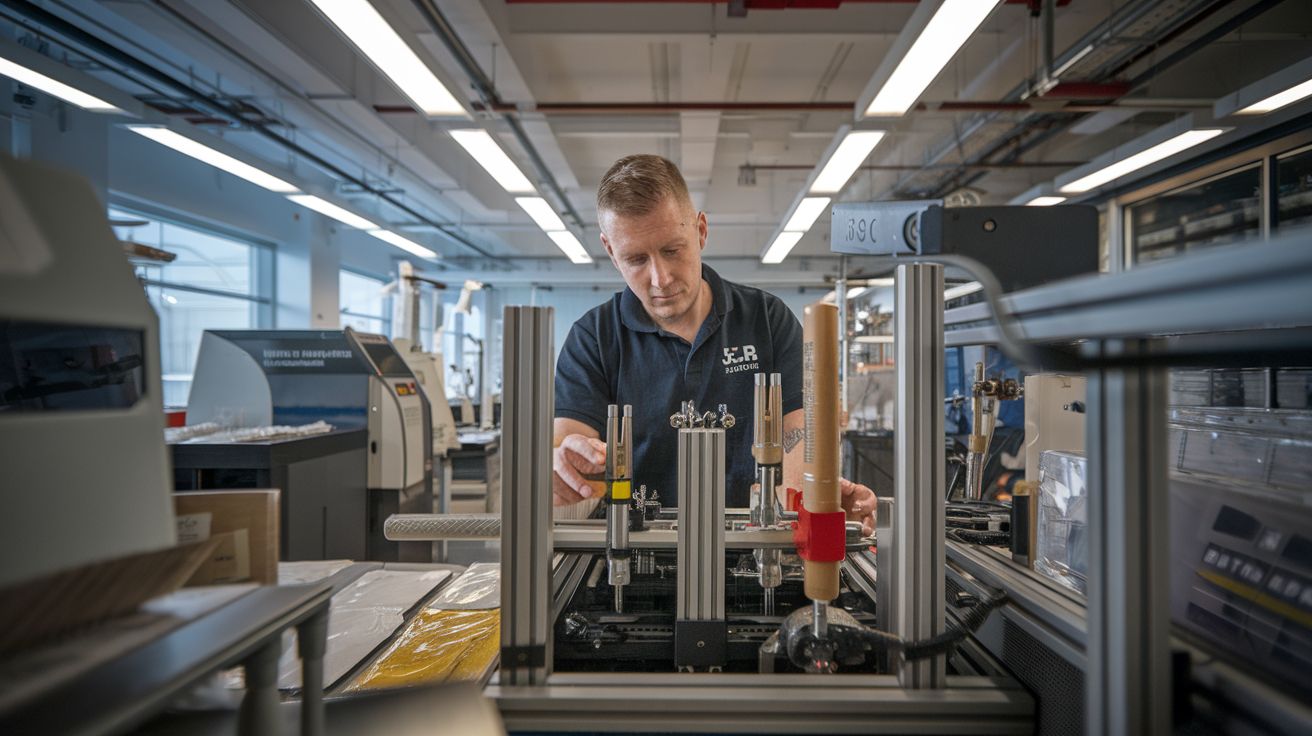

The day begins bright and early for a J&B hottack tester operator. As the sun peeks over the horizon, these experts are already immersed in preparation, ensuring that all equipment is calibrated and ready for a day of rigorous testing. Working with advanced instruments like the J&B Hot Tack 3000, 4000, and the sophisticated 5000 MB Tester, they meticulously inspect these machines to adhere to the ASTM F1921-12 test method, which is crucial for accurate results.

With a keen eye, they check every parameter: temperature settings, pressure levels, and seal times. These initial tasks might seem mundane to an outsider, but they are the backbone of reliable daily tasks hottack testing. One slip, and the whole day's results could be compromised. It's fascinating how such attention to detail is a routine part of the job, ensuring the precision that defines our work.

Discover the automatic mode of our J&B Heat Seal Testers | Vived ManagementDiscover the automatic mode of our J&B Heat Seal Tester. |

The Packaging Tester Routine: Unraveling Material Mysteries

Once the machines are ready to roll, it's time for the packaging tester routine to kick into full gear. Understanding the intricate properties of each packaging material is where the magic happens. Operators take various samples, often provided by international chemical companies relying on our expertise. Each sample represents not just a material but a promise of quality and safety for the products it will eventually hold.

The operator runs each sample through the hottack testers, observing how well they seal under heat and pressure. This process tells a story of its own—about durability, reliability, and performance. By analyzing these factors, operators can suggest improvements or validate existing solutions, ensuring every package stands up to real-world challenges. This meticulous testing routine is essential for maintaining the high standards that our clients expect and deserve.

The magic behind Vived Management's high precision materials testing | Vived ManagementThe magic behind Vived Management's high precision materials testing |

Afternoon Analysis: Diving Deep into Data

Ah, the beauty of data! After a bustling morning of testing, the afternoon is dedicated to analysis. This part of the day in the life of a J&B hottack tester operator is all about diving into numbers, graphs, and patterns. It's here that the true depth of expertise comes to light. Operators interpret the data, looking for trends and anomalies that could indicate anything from a slight tweak needed in the manufacturing process to a complete overhaul.

These insights feed into Vived Management's broader mission of innovation and client success. By aligning hot tack technology with evolving demands, we don't just keep up with the market; we strive to predict and shape its future. This analytical phase is crucial for turning raw data into actionable strategies that drive continuous improvement.

Demystifying the complexity of packaging testing: A Vived Management perspective | Vived ManagementDemystifying the complexity of packaging testing: A Vived Management perspective |

Collaboration and Communication: Bridging Expertise and Action

No man is an island, and neither is a hottack tester operator. Communication and teamwork play a pivotal role in the daily operation. Interacting with engineers, product developers, and Vived Management's international clients requires not only technical know-how but also the knack for translating complex data into actionable insights.

Regular team meetings and client consultations ensure that everyone is on the same page, working cohesively towards enhancing the performance of our clients' packaging solutions. This collaborative effort is what transforms individual expertise into collective success, ensuring that our solutions are both innovative and practical.

Understanding ASTM F1921-12 - the standard that defines quality in packaging | Vived ManagementUnderstanding ASTM F1921-12 - the standard that defines quality in packaging |

Closing the Day: Ensuring Continuity and Excellence

As the day winds down, the J&B hottack tester operator concludes with a final check. Machines are powered down, notes are compiled, and results are logged meticulously. This might seem like the end of a day, but in reality, it's the beginning of a new cycle of constant improvement and innovation.

Through the lens of a day in the life of a J&B hottack tester operator, it's clear that the role is integral to the success of Vived Management's offerings. Their expertise ensures our clients receive nothing short of excellence in flexible packaging solutions, reaffirming our commitment to quality and innovation.

Contact Us

Curious to learn more about how our operators and equipment can support your packaging needs? Reach out to Vived Management at info@vived-management.be or visit us at https://www.vived-management.be/. Whether it's enhancing your operational speed or ensuring product reliability, our team is eager to assist you in achieving unparalleled success in your packaging endeavors.